Friction depends a lot on the surfaces involved. Rough surfaces, like concrete, create more resistance because they have irregularities that catch on each other. Smoother surfaces, like polished marble, slide more easily. Lubrication, such as oil or grease, forms a film that reduces direct contact and lowers friction. Different lubricants and surface textures affect how much force you need to move objects. Keep exploring to understand how these factors work together to influence friction and surface interactions.

Key Takeaways

- Friction varies with surface roughness; rougher surfaces increase resistance compared to smoother ones.

- Surface interactions at the microscopic level determine how much force is needed to slide objects.

- Lubricants reduce friction between surfaces by forming a film that prevents direct contact.

- The effectiveness of lubrication depends on the lubricant type, thickness, and surface material properties.

- Understanding surface differences helps optimize movement, reduce energy use, and extend machinery lifespan.

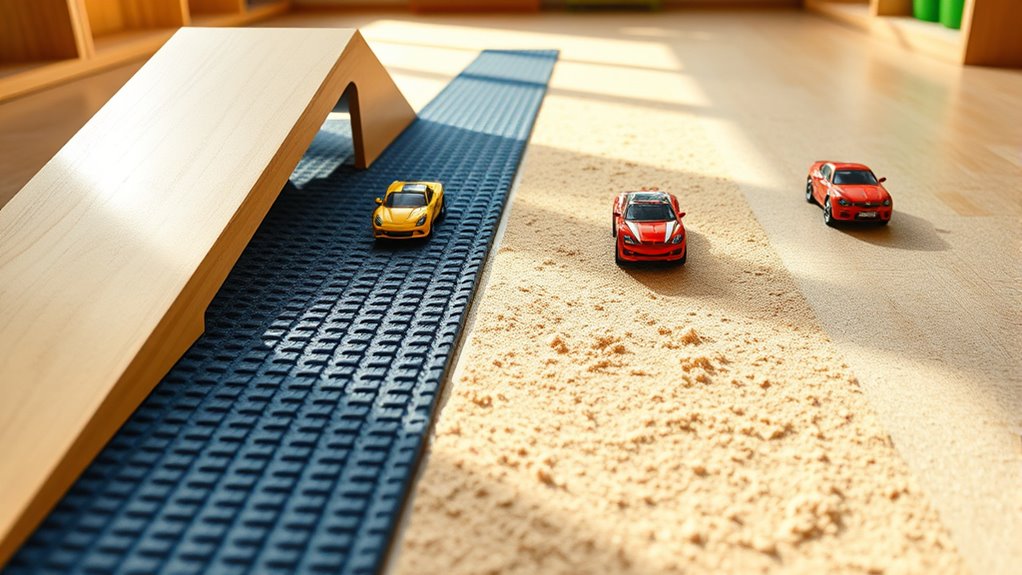

Have you ever wondered what causes objects to resist sliding past each other? The answer lies in the force called friction, which depends heavily on the nature of the surfaces involved. When you slide two objects against each other, their surfaces interact at a microscopic level, and this interaction is influenced by the effects of surface roughness. Rougher surfaces have more irregularities and peaks that catch on each other, increasing friction. Conversely, smoother surfaces tend to slide more easily because there are fewer imperfections to grip each other. The effects of surface roughness are essential because they determine how much force you need to move an object across a surface. For example, a rough concrete floor provides more resistance than a polished marble surface. Understanding this can help you control movement, whether you’re designing machinery or simply trying to push a heavy box.

But it’s not just about how rough a surface is; the role of lubrication plays a major part in reducing friction. Lubricants, such as oil, grease, or even water, create a thin film between the surfaces, preventing direct contact of the rough peaks. This film acts like a barrier, drastically lowering the effects of surface roughness and making it easier to slide objects past each other. When you apply lubrication, you’re effectively decreasing the frictional force needed to move an object, which can save energy and reduce wear and tear on surfaces. For instance, lubricating bicycle chains or car engines minimizes resistance and extends their lifespan. The role of lubrication becomes even more vital in industrial settings where machinery operates continuously, and reducing friction can mean significant savings in energy and maintenance costs.

Furthermore, the type of lubricant and how well it spreads over the surface can influence the level of friction reduction. Thicker lubricants tend to stay in place better, providing longer-lasting protection, while thinner ones might be ideal for delicate, precise movements. It’s also important to note that over-lubrication can sometimes cause issues, like attracting dirt or causing slipping where you don’t want it. Hence, selecting the right kind of lubricant and applying it properly is key to controlling friction effectively. Additionally, the effectiveness of reducing friction through lubrication can be enhanced by understanding the impact of surface material properties on how well lubricants work. By understanding the effects of surface roughness and the role of lubrication, you can manipulate how objects move across different surfaces, making tasks easier or more efficient. Whether you’re working on mechanical projects or just trying to slide a stubborn drawer open, knowing these factors helps you make smarter choices about how surfaces interact and how to manage their resistance.

Frequently Asked Questions

How Does Temperature Affect Surface Friction?

Temperature affects surface friction by altering material adhesion and causing thermal expansion. As temperature rises, materials tend to expand, which can reduce contact and decrease friction. Conversely, cooling can increase adhesion, making surfaces stick more. Higher temperatures may also weaken surface bonds, lowering friction, but in some cases, thermal expansion can increase contact pressure, raising friction. So, temperature changes can either increase or decrease surface friction depending on the materials involved.

Can Friction Be Completely Eliminated?

Friction can’t be completely eliminated, as it’s a fundamental force. Interestingly, in sports, athletes reduce friction with specialized gear, while in machinery, lubricants minimize it for efficiency. Even with advanced technology, some friction always remains to provide control and safety. So, you can notably reduce it, but total elimination isn’t possible because friction is essential for movement and grip.

How Does Surface Roughness Influence Friction?

Surface roughness directly influences friction by affecting the surface texture, which determines how much contact occurs between surfaces. Smoother surfaces typically have a lower coefficient of friction, reducing resistance, while rougher textures increase it. Variations in the coefficient reflect changes in surface roughness, meaning that as you alter the surface texture, you change how much friction there is. So, rougher surfaces generally lead to higher friction, and smoother ones decrease it.

What Materials Create the Least Friction?

Imagine sliding a boat smoothly over glassy water—you experience minimal resistance. Materials like Teflon and polished metals create the least friction because their surfaces are smooth and often paired with effective lubricants. By carefully selecting lubricants and polishing surfaces, you reduce roughness and enable objects to glide effortlessly. This combination acts like a gentle, frictionless current, making movement easier and more efficient in mechanical systems.

How Does Friction Impact Energy Efficiency?

Friction reduces energy efficiency by converting useful mechanical energy into heat, making machinery work harder. You can improve efficiency by using lubrication methods like oil or grease, which decrease friction in machinery. Regular maintenance ensures these lubricants work effectively, minimizing energy loss. When you manage friction well, your equipment runs smoother, consumes less power, and lasts longer, saving you money and reducing wear and tear over time.

Conclusion

Now that you understand how different surfaces affect friction, you can see it’s not just black and white. Each surface offers a unique challenge, and knowing how they behave helps you make smarter choices in everyday life. Remember, it’s all about playing your cards right—sometimes smooth sailing, other times a rough ride. Keep experimenting and observing, because the more you learn, the better you’ll get at handling friction’s twists and turns.